Keeping Utility Contractors Safe: A 2024 Guide

Utility contractors are critical to completing many projects but face unique risks when performing their duties. Hiring clients must help them avoid these hazards by identifying them and taking mitigation steps.

However, this process can sometimes prove challenging. Many potential hazards in the utilities industry are subtle and can go unnoticed. Even after identifying them, hiring clients might need help taking the proper steps to protect their workers better.

This article lists and discusses five common workplace risks for every utility worker and seven steps hiring clients might take to avoid them.

5 Common Workplace Risks to Utility Contractors

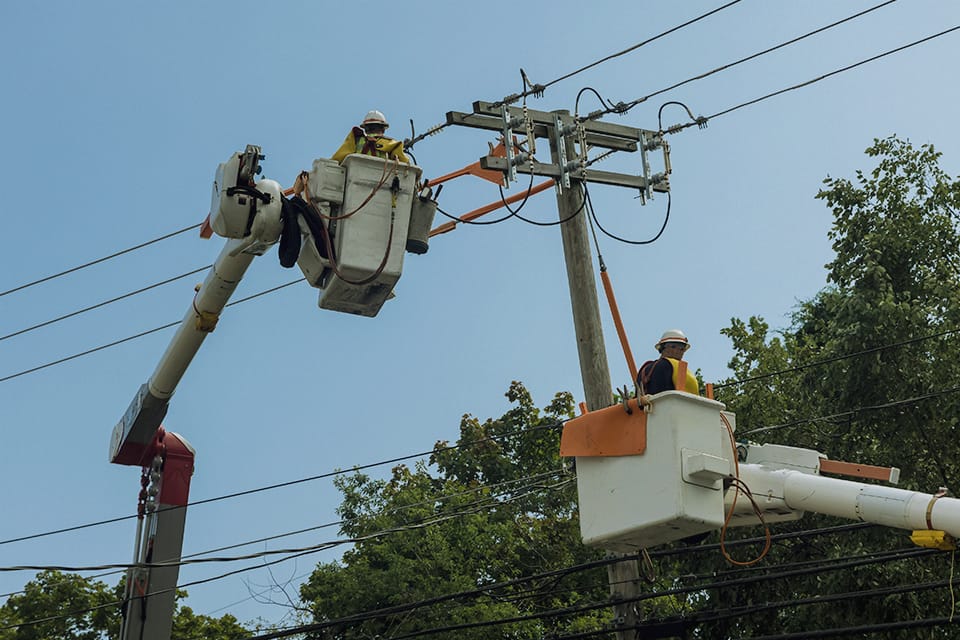

1. Electrocution

Electrocution is a health and safety risk that exposes utility contractors in various work settings to severe risks. The resulting injuries can be disastrous if hiring clients do not establish the appropriate policies, procedures, and training.

Specific tasks that pose substantial risks include coming into contact with the following:

- Electrical lines

- Switchgear components

- Energized pipes

- Conductors

2. Slips, Trips, and Falls

Falls are also a typical job site hazard in the utilities industry. Contractors working from tall heights without the proper equipment and precautions are at serious risk of injury or death. However, by establishing the right safety policies and periodic training, hiring clients can significantly reduce the likelihood of injury.

3. Exposure to Toxic Chemicals

Utility contractors encounter several harmful substances, including but not limited to the following:

- Lead

- Mercury

- Mold

- Asbestos

- Silica dust

Unlike heavy equipment or visibly unstable platforms, these types of hazards are more challenging to spot, and their dangers are less noticeable. However, exposure to high doses can cause severe health issues.

4. Fires and Explosions

Everyday utility job site tasks like welding and vehicle operation introduce potential combustion risks that can result in fires in areas near fuel sources. Any uncontrolled fire concerns workers, but fires with a sustained fuel source are earnest.

While site workers can usually put out small fires using fire extinguishers and blankets, larger ones with a sustained fuel source are significantly more difficult to contain and produce long-lasting blazes with a higher risk of causing severe injuries or fatalities.

5. Confined Spaces

Confined spaces are not necessarily designed for worker occupancy and typically have limited or restricted means of entry or exit. However, workers still enter them, posing a substantial threat. They are dangerous not only because of their limited room but also because of their potential to trap toxic substances.

7 Safety Procedures to Ensure Utility Contractor Safety

1. Conduct a Proper Hazards and Risks Assessment

The best safety plans start with a proper risk assessment, helping the hiring client find and minimize hazards before they can do harm. These reports should document all potential dangers to develop a comprehensive safety plan.

Safety professionals should regularly assess the site to stay updated on the newest dangers that put workers at risk.

2. Establish a Communication System

A reliable communication channel system is also crucial for utility contractor safety, especially in providing details to complete a successful emergency response.

These details include but are not limited to the following:

- Site location

- Pertinent safety hazards

- The individuals onsite

- Dangerous situations like confined spaces, tunnels, and heights

The more information hiring clients can provide workers about the surrounding environment, the better they can respond to an emergency.

3. Comply with Legislation and Regulations

Local legislation and OHS-related regulations evolve constantly as the industry landscape changes, presenting new safety challenges for hiring clients.

However, if the hiring client does not comply, they are putting workers in harm’s way and exposing the company to potential litigation and damage to their public image.

4. Stay Up-to-Date on PPE

Utility contractors work in various settings and, as a result, require different PPE at different times.

For example, electrical utility workers face the risk of fatal burns and shocks every day, while water utility workers encounter toxic chemicals and biological hazards.

The personal protective equipment (PPE) hiring clients supply to workers significantly impacts their safety while on the job. As such, all companies should research the ideal PPE for their workforce, given its specific duties.

Examples of essential PPE include the following:

- Hard hats

- Face shields

- Masks

- Gloves

- Safety goggles

- Flame-resistant uniforms

- Shoe covers

5. Require Safety Check-ins

Workers often perform tasks at multiple locations, making it more difficult for hiring clients to know if they’re safe. However, the hiring client can confirm their workforce’s safety by requiring each utility contractor to check in after every shift.

These check-ins can come via phone calls or a recording of their status on paper or an office whiteboard. Alternatively, to set up a more effective system, hiring clients can also implement an automated system that notifies managers of missed check-ins and emergencies.

6. Practice Proper Maintenance and Cleaning of Work Areas

Although falls can pose a threat to safety in any workplace, they are significantly more hazardous in areas that are not organized and cleansed on a regular basis. Trips over obstacles such as debris and cluttered cables can cause potentially severe bodily harm.

In areas of substantial hazards, hiring clients might consider eye-catching signage to alert personnel to restricted areas where they are not permitted to enter.

7. Properly Manage Journeys for Remote Utility Contractors

Utility workers often visit several worksites, sometimes in rural and remote locations. As a result, these workers might encounter a number of journey management hazards, including the following:

- Driver fatigue

- Poor road conditions

- Motor vehicle accidents

- Hazardous weather

- Wildlife-vehicle collisions

To mitigate these remote work-related risks, hiring clients should provide workers with emergency kits and high-quality location monitoring and communication devices.

Utility Worker Safety Requires the Best Risk Management Solutions

Utility contractors are essential to your business, and you should take all the precautions necessary to ensure their safety on your worksite. While the abovementioned measures are a step in the right direction, the execution of your safety program is only as effective as the safety solutions you employ.

Consider partnering with us to configure a solution that meets the needs of you and your workers.

Contact us today to learn more.