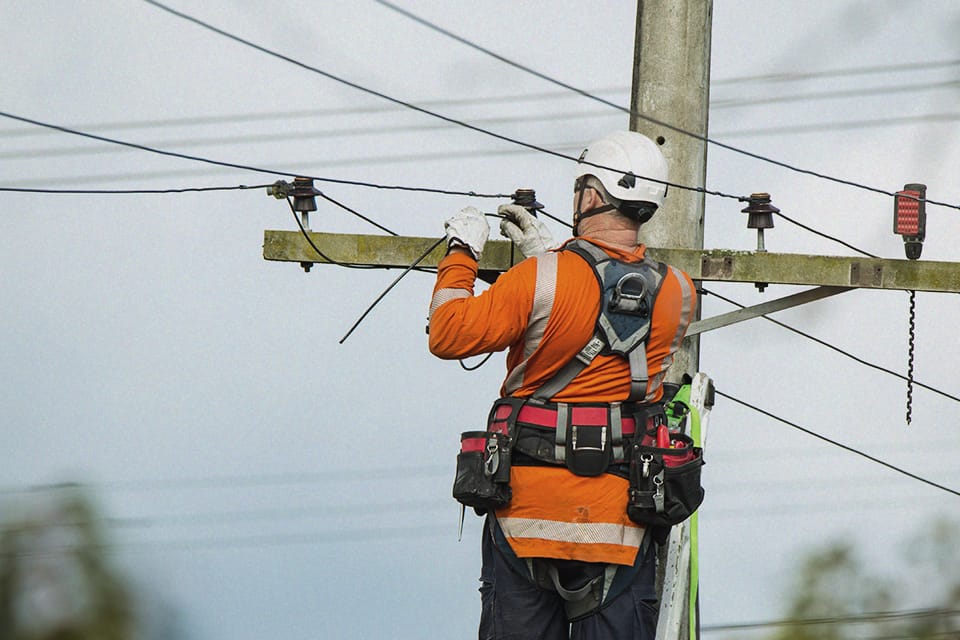

Ensuring Contractor Safety During Utility Turnarounds

Turnarounds are hectic by design. They involve short maintenance windows where plants go offline, contractor headcounts surge, and full-time staff shift roles. Everyone’s racing to restore operations. Even experienced teams face higher risk during these events, so contractor safety must come first.

The stakes are high: Between 2011 and 2021, there were more than 1,100 serious injuries and fatalities (SIFs) in the utilities sector in the U.S., according to the Bureau of Labor Statistics.

Workers in the utilities sector face a significantly higher risk of SIFs compared to other industries like construction, manufacturing, or mining, according to a DEKRA study of more than 1,000 incidents across major electric, gas, and water organizations. The SIF exposure rate in utilities is 32%, seven points higher than the all-industry rate, and reaches 42% in the water sector alone.

Beyond the human cost, the financial risk is steep. When a turnaround runs over schedule, delayed production can cost facilities hundreds of thousands of dollars in lost revenue. That’s why careful planning and strict adherence to timelines aren’t just helpful; they’re essential.

Turnaround time is another factor. At industrial facilities, planned maintenance periods usually happen in the spring or fall, when weather conditions are most stable, and can last anywhere from a few days to several weeks or even months. In some cases, only part of the plant is taken offline, allowing a minimum level of production to continue during the work.

In this high-pressure environment, contractor safety can’t just be a policy. It must be built into every step.

Here are three high-impact best practices to reduce incident risk, improve contractor safety, and maintain control during utility turnarounds.

Enforce Lockout/Tagout (LOTO) with Absolute Precision

In turnaround safety, energy isolation is non-negotiable. All equipment undergoing manufacturing must be completely de-energized, locked out, and tagged out in accordance with OSHA 1910.147. With multiple contractors and rotating crews on-site, coordination failures can be fatal. For example, a missed shift handoff could lead a worker to assume a motor is de-energized when it’s not, causing unexpected startup and serious injury.

What to implement: Use digital LOTO tracking systems that provide real-time verification of isolation status and lockout assignments. Require auditable checklists and mandate supervisor sign-off before any work begins.

Make Contractor Safety the Focus of Confined Space Entry

Tasks inside tanks, ducts, or turbine housings involve high-risk conditions, from low oxygen to engulfment, and demand strict controls. That’s why contractor safety depends on OSHA 1910.146-compliant confined space procedures. Without proper permits, testing, and attendants, workers face serious danger. A crew member entering a tank without realizing oxygen is low could collapse before being found.

What to implement: Require current confined space certifications for all entrants and attendants and deliver site-specific training as part of onboarding. Use digital access control to restrict entry to authorized personnel only and validate real-time permit status before work begins.

Enforce Respirator Readiness — from Fit Testing to Facial Hair Compliance

Respiratory protection is common in turnaround safety due to airborne hazards like dust, vapor, and heat. But it only works if OSHA 1910.134 standards are followed. A common issue is facial hair breaking the respirator seal. In one case, a worker with a beard entered a dusty area, wore a respirator, and still suffered irritation. The seal had failed under pressure.

What to implement: Provide worker training for all respirator users. Make sure they are medically cleared and properly fit-tested. Enforce a no-facial-hair policy for tight-seal models. Use digital systems to flag expired certifications or missed fit tests during check-in.

Contractor Safety Starts with Systems That Enable Control

While LOTO, confined space procedures, and respirator readiness are essential to reducing risk, they’re only as effective as the systems that support them. In fast-paced settings, contractor safety improves when built into workflows, not added later.

The right systems don’t just check boxes. They enable operational control at scale by:

- Showing who is on-site and what they’re cleared to do

- Helping supervisors spot compliance or task-readiness issues

- Preventing errors during shift handoffs with centralized, auditable data

- Reducing communication breakdowns and paper processes

- Blocking untrained or unqualified workers from high-risk areas

When safety is built into task assignments, crew organization, and site access, it becomes a performance driver, not a roadblock.

Turnarounds will always be complex. But with the right contractor management platform, and practices, mitigating contractor safety risk is possible. Our contractor management platform helps utility operators stay compliant, protect lives, and avoid costly delays during turnarounds. From LOTO verification to training validation and access control, contact us to learn more about our risk management technology and services.