What is Lockout / Tagout Training?

In today’s industrial landscape, safety is paramount. Among the critical safeguards, Lockout / Tagout (LOTO) procedures prevent injuries when energy is unexpectedly released during machinery and equipment servicing.

Effective Lockout / Tagout training equips workers with the knowledge and skills to implement these life-saving procedures, fostering a culture of safety that protects employees and ensures smooth operations.

This article discusses the Lockout / Tagout concept and explores the essential topics that comprehensive LOTO training should encompass.

Understanding Lockout / Tagout: A Core Safety Principle

LOTO is a systematic approach to controlling hazardous energy during servicing or maintenance activities. Its primary purpose is to prevent the accidental startup or release of energy, protecting workers from serious injuries or even death.

The Occupational Safety and Health Administration (OSHA) mandates LOTO standards, ensuring consistent implementation across workplaces.

Why is Lockout / Tagout Training Crucial?

Failing to implement LOTO procedures properly can have devastating consequences. Unexpected equipment energization during maintenance can lead to severe injuries, fatalities, and even property damage.

LOTO training empowers workers to identify hazardous energy sources, select the appropriate lockout devices, and follow established procedures to ensure a safe work environment.

Benefits of Effective Lockout / Tagout Training

Investing in comprehensive LOTO training offers a multitude of benefits for businesses and employees alike:

Enhanced Worker Safety

LOTO training equips workers with the knowledge and skills to protect themselves from hazardous energy sources during maintenance tasks.

Reduced Risk of Accidents and Injuries

Following the right LOTO procedures significantly reduces the risk of accidents caused by unexpected equipment activation.

Improved Compliance with Regulations

OSHA’s Lockout / Tagout Standard (29 CFR 1910.147) outlines specific requirements for LOTO procedures. Proper training ensures compliance with these regulations.

Minimized Downtime

By preventing accidents and injuries, LOTO procedures contribute to smoother operations and minimize downtime due to accident investigations and repairs.

Boosted Employee Morale

A strong safety culture fosters trust and demonstrates an employer’s commitment to worker well-being, leading to higher morale and employee satisfaction.

Essential Topics for Effective Lockout / Tagout Training

To be truly effective, Lockout / Tagout training should go beyond merely explaining the procedures. A well-rounded program should encompass the following key aspects:

Identifying Hazardous Energy Sources

The training should include defining different types of hazardous energy that can pose risks during maintenance activities, such as:

- Mechanical energy

- Electrical energy

- Hydraulic and pneumatic energy

- Thermal energy

Understanding Standards and Regulations

As mentioned earlier, understanding the legal framework is crucial. The training should cover relevant OSHA standards that mandate LOTO implementation and ensure consistent workplace safety protocols.

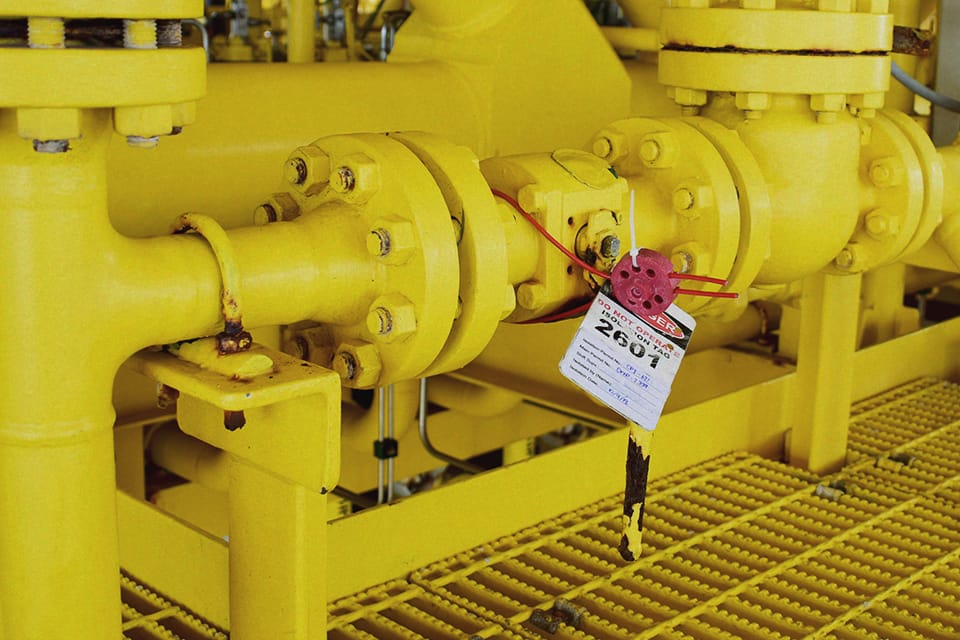

Identifying Energy Isolation Devices

Employees need to be familiar with the various lockout devices used to isolate different energy sources, including but not limited to the following:

- Locks

- Tags

- Plugs

- Blinds

The training should emphasize the proper selection and application of these devices for different situations.

Defining Roles and Responsibilities

Effective LOTO procedures rely on a clear understanding of roles and responsibilities. The training clarifies these roles to ensure everyone involved acts safely, including the following:

Authorized Employees

Individuals with the knowledge, skills, and experience to apply LOTO procedures.

Affected Employees

Workers whose jobs involve operating or working near equipment undergoing maintenance.

Supporting Personnel

Individuals who may not directly work on equipment but could be impacted by LOTO procedures.

Understanding a Lockout / Tagout Program’s Requirements

A comprehensive LOTO program is the foundation for effective energy control. The training should delve into the program’s components, ensuring everyone understands how the program functions:

Establishment, Development, and Maintenance

This involves creating a written LOTO program specific to your workplace.

Program Components

This topic should cover essential elements like LOTO procedures, training plans, and energy control devices.

Inspections and Recordkeeping

All personnel should understand the importance of regularly verifying the effectiveness of LOTO procedures and maintaining records.

Using a Lockout / Tagout Procedure Properly

Understanding the theory behind LOTO is essential, but effective safety comes from applying that knowledge in practice. LOTO training equips workers with the skills to implement LOTO procedures confidently.

Beyond Training: Building a Culture of Safety

While comprehensive training is a vital first step, building a lasting safety culture requires a multi-pronged approach. Here are some essential elements:

Management Commitment

Management should actively support LOTO procedures by allocating resources for training, providing proper lockout devices, and holding employees accountable for safe work practices.

Ongoing Communication and Reinforcement

Safety reminders, periodic refresher training sessions, and open communication channels to address safety concerns are crucial for sustaining a culture of safety.

Employee Participation and Empowerment

Encouraging employee participation in safety discussions, hazard identification, and near-miss reporting fosters a sense of ownership and accountability for safety within the workforce.

Incentivize Safe Behavior

Programs that recognize and reward safe work practices can further motivate employees to prioritize safety.

Choose the Industry’s Best LOTO Training to Ensure a Safe and Efficient Future

Lockout / Tagout training is essential for creating a strong safety culture in workplaces that use machinery and equipment. Companies can reduce accidents by carefully training employees to follow LOTO procedures, preventing injuries and ensuring safety for all.

Investing in comprehensive Lockout / Tagout training is an investment in the well-being of your workers, the smooth operation of your business, and a future where safety remains a top priority.

However, that investment is only as worthwhile as you’re the training program you choose to offer. The course’s curriculum should include all the topics discussed above to ensure you’re providing teams with the best possible safety education.

Allow Veriforce’s Lockout / Tagout training to equip your workforce with the knowledge and skills to service equipment and machinery safely.

Contact us today to learn more.