Supply Chain Lessons From the Texas Deep Freeze

Risk Management Must Be Proactive

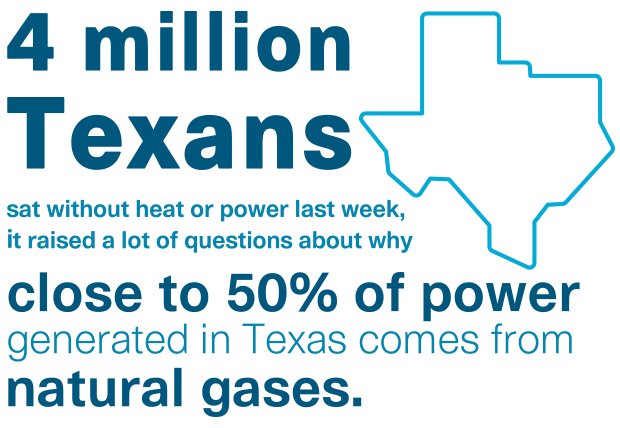

As nearly 4 million Texans sat without heat or power last week, it raised a lot of questions about why close to 50% of power generated in Texas comes from natural gases or why 46,000 megawatts sat offline in one day. From a procurement perspective, it’s easy to dismiss the rolling blackouts and natural gas disruption in Texas as a “Black Swan” event. But we would be remiss to ignore the lessons learned around how critical it is to proactively put resiliency measures in place with suppliers — in this case, critical suppliers who are responsible for the light and heat of millions of people.

Veriforce interviewed Jason Busch, founder and procurement industry technology best practices resource at Spend Matters, to gain his perspective on takeaways related to procurement and supply chain.

“Where I come from in the Midwest, it’s easy to say ‘I told you so’ about the risk of freezing temperatures and any type of pipeline or grid infrastructure. But what happened in Texas was truly extraordinary from a weather perspective,” he observes. “The system was simply not built for an outlier event like this.”

Busch suggests that while we can never be fully prepared for every contingency in terms of equipment and supply chain failures, especially if they fall outside the bounds of expected conditions, “we can proactively put mitigation plans in place, which include our suppliers.”

https://www.texastribune.org/2021/02/19/texas-winter-legislature-electricity/.

https://www.texastribune.org/2021/02/19/texas-winter-legislature-electricity/.

Part of the challenge, Busch notes, is that energy and utility companies have spent years focused on cost reduction in procurement, often without putting the same emphasis on supply chain risk management and mitigation as on purchase price variance, commodity/category management, strategic sourcing and transactional procurement. Beyond cost savings, “preparing proactively to take mitigative steps in the event of a crisis is essential.”

This starts with having access to the right set of “ready” suppliers, Busch observes. “Supplier management begins with having a supplier and contractor onboarding process that is proactive, so you have instant access to information that will help you deploy the right internal and external assets when and where they are needed,” he notes.

As important, Busch suggests, is realizing where you sit in the pecking order with key vendors when any crisis does occur.

Take the current semiconductor chip shortage in the automotive industry, for example. Semiconductors are in short supply around the world, which is just one reason President Joe Biden signed an executive order to review American supply chains. As that 100-day review happens at a Federal level, we can’t stress enough how important it is for procurement organizations to simultaneously review their suppliers.

So, what’s a procurement manager to do?

- Create a mitigation plan before disaster hits

Work with your suppliers to understand what they can expect from you and what you can expect from them if a crisis occurs or demand fluctuates quickly - Ensure that safety, compliance, and insurance is always up to date with suppliers

In a crisis, business continuity comes first. The last thing you want to worry about is lapsed safety certifications, fines, or filing fruitless insurance claims - Have a pivot plan

Having a robust, wide-net supplier base will limit the chances that one hiccup will wreck your entire supply chain

Be prepared for unexpected events that could impact your supply chain.

If you would like to talk to an expert at Veriforce that helps clients manage third-party suppliers, please reach out using the form here.